Products Category

Mobile Crusher & Screener

Mechanical Equipment Products

Intelligent Mining Equipment

Intelligent Tunnel Mechanical Equipment

Mechanical Equipment for Underground Engineering

Non-coal Mine Mechanical Equipment

Construction Mixing Plant Equipment

Coal Mining Machinery and Equipment

All Products

Coal Mine Bolter Miner

Coal Mine Exploration Drilling Rig

Coal Mine Roadway Rehabilitation Machine

Coal Mine Roof Bolter

Coal Roadheader

Crawler-Type Hydraulic Drilling Jumbo for Coal Mines

Drilling and Loading Unit for Coal Mines

Hydraulic Roof Support

Monorail Hydraulic Roof Bolter for Coal Mines

Generator Set

Petroleum, Oil & Gas, and Petrochemical Equipment

Marine, Offshore & Port Systems

Heavy Machinery Components and Parts

Used Machinery and Electromechanical Equipment

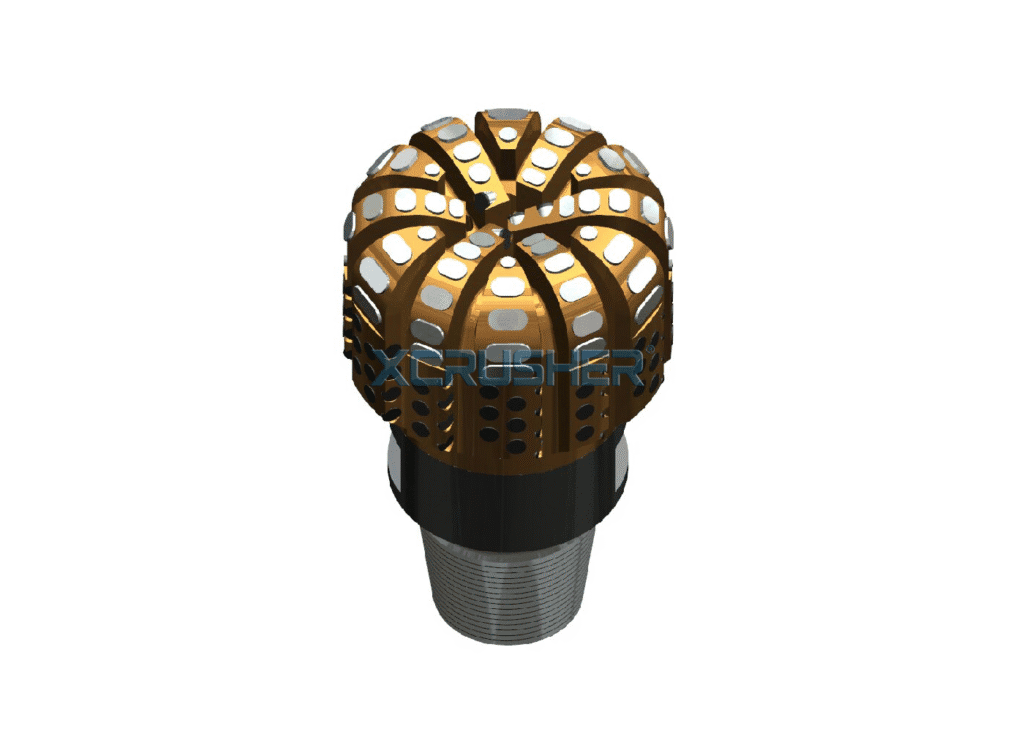

Drill Bit & Drill Tools

Drill bits are critical components in oil and gas drilling operations, designed to crush or cut through subsurface formations to create a wellbore. CNPE offers a full range of high-performance drill bits tailored for various geological conditions and drilling techniques. These bits are engineered with precision to deliver superior rate of penetration (ROP), extended durability, and optimal directional control.

Product Categories:

-

PDC Bits (Polycrystalline Diamond Compact Bits): Designed for high-speed, efficient drilling in soft to medium-hard formations. Known for their wear resistance and long life, PDC bits are available in matrix-body and steel-body designs with various blade counts and cutter configurations.

-

Roller Cone Bits (Tricone Bits): These bits are suitable for a wide range of formations, especially medium to hard rock. Available in two main types:

-

Milled Tooth Bits – Ideal for soft to medium formations, equipped with steel teeth.

-

Tungsten Carbide Insert (TCI) Bits – Designed for harder formations, using tungsten carbide inserts for enhanced wear resistance.

-

-

Single Cone Bits: Used for specific applications such as directional drilling and re-entry wells. They offer better stability in soft and plastic formations.

-

Hole Openers (Reamers): Applied in borehole enlargement operations, especially in horizontal and directional wells. Available in fixed or replaceable arm configurations to accommodate various diameters.

-

Underreamers: Downhole tools used to enlarge the borehole below casing or restrictions, commonly employed in expandable casing and deep well applications.

-

Core Bits: Designed to extract cylindrical rock samples for geological analysis. Available in diamond-impregnated or surface-set configurations.

-

Percussion Bits (Hammer Bits): Utilized in air drilling systems, particularly effective in hard and abrasive formations. These include button bits for down-the-hole (DTH) hammers and top hammer drilling.

All CNPE drill bits undergo rigorous quality control and are manufactured to meet or exceed API and ISO standards. With advanced cutting structure design, optimized hydraulics, and robust bearing systems, our drill bits ensure reduced downtime, improved drilling efficiency, and cost-effective performance across all drilling environments.