Products Category

Mobile Crusher & Screener

Mechanical Equipment Products

Intelligent Mining Equipment

Intelligent Tunnel Mechanical Equipment

Mechanical Equipment for Underground Engineering

Non-coal Mine Mechanical Equipment

Construction Mixing Plant Equipment

Coal Mining Machinery and Equipment

All Products

Coal Mine Bolter Miner

Coal Mine Exploration Drilling Rig

Coal Mine Roadway Rehabilitation Machine

Coal Mine Roof Bolter

Coal Roadheader

Crawler-Type Hydraulic Drilling Jumbo for Coal Mines

Drilling and Loading Unit for Coal Mines

Hydraulic Roof Support

Monorail Hydraulic Roof Bolter for Coal Mines

Generator Set

Petroleum, Oil & Gas, and Petrochemical Equipment

Marine, Offshore & Port Systems

Heavy Machinery Components and Parts

Used Machinery and Electromechanical Equipment

Petroleum, Oil & Gas, and Petrochemical Equipment

Petroleum, oil & gas, and petrochemical equipment encompasses a wide range of specialized machinery and systems used throughout the entire lifecycle of energy production — from exploration and extraction to transportation, refining, and petrochemical processing.

Key Equipment Categories:

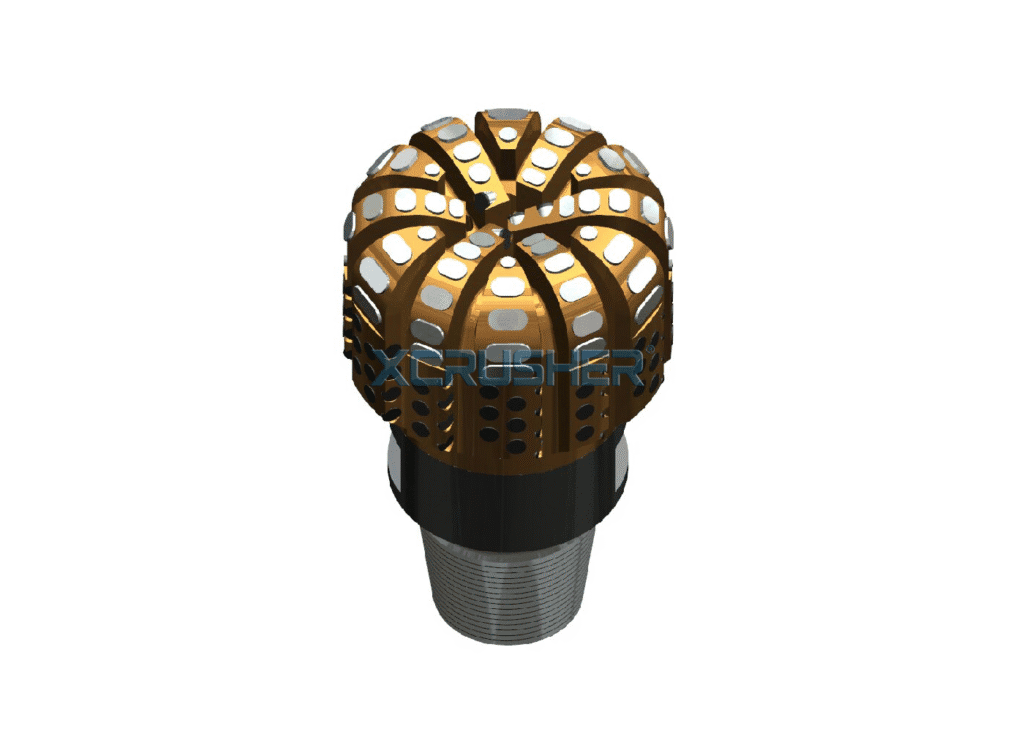

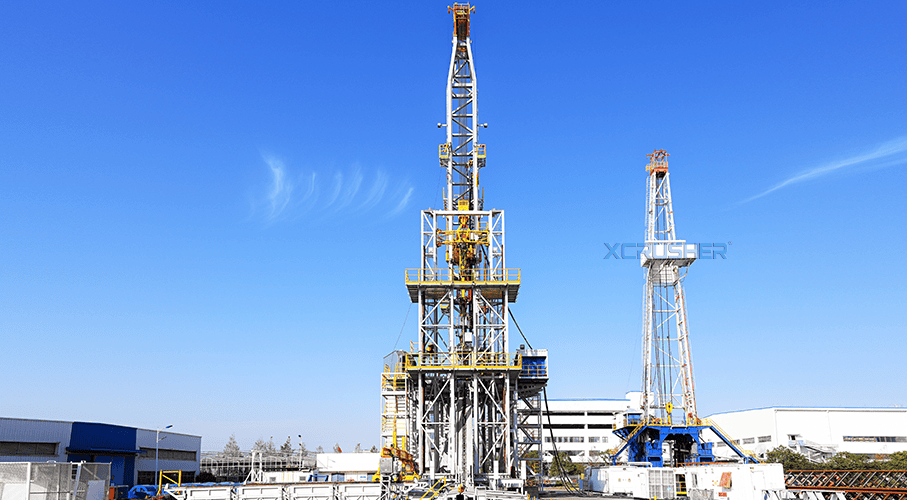

1. Drilling Equipment

Used for vertical or directional drilling to access underground oil and gas reservoirs. Includes:

-

Land and offshore drilling rigs

-

Drill bits and downhole tools

-

Mud pumps and solids control systems

2. Pumping Equipment

Extracts and transports crude oil, natural gas, or chemicals. Common systems include:

-

Beam pumps and submersible pumps

-

Multiphase pumps

-

Hydraulic fracturing pumps

3. Oil & Gas Separation Equipment

Separates oil, gas, and water mixtures extracted from wells:

-

Three-phase separators

-

Desalting units

-

Degassers and coalescers

4. Offshore Platforms and Marine Extraction Systems

Specialized offshore rigs and production platforms, designed for:

-

Deep-sea drilling

-

Harsh marine environments

-

Floating production storage and offloading (FPSO) units

5. Refining and Petrochemical Processing Units

Used to process crude oil into refined products and chemical derivatives:

-

Distillation columns

-

Hydrocrackers and catalytic reformers

-

Reactors, heat exchangers, and pressure vessels

6. Storage and Transportation Equipment

Includes:

-

LNG storage tanks

-

Pipeline systems and compressor stations

-

Oil tankers and loading arms

7. Instrumentation and Control Systems

For automation, safety, and efficiency monitoring:

-

SCADA and DCS systems

-

Flame detectors, pressure/flow sensors

-

Explosion-proof electrical components

Technical Features and Advantages:

-

High Operational Efficiency: Engineered for continuous operation in challenging conditions such as offshore platforms, desert oilfields, arctic zones, and deep wells.

-

Advanced Automation: Many systems feature integrated intelligent controls and remote monitoring, reducing human error and improving yield.

-

Robust Safety Design: Multilayer safety protocols, explosion-proof designs, and corrosion-resistant materials enhance operational safety.

-

Environmental Compliance: Modern equipment is optimized to reduce emissions, energy consumption, and waste, aligning with ESG and global carbon reduction targets.

-

Customization Capabilities: Modular and scalable design enables tailored solutions for specific field requirements — from small onshore operations to ultra-deepwater platforms.

These integrated technologies form the backbone of modern energy infrastructure, ensuring safe, efficient, and environmentally responsible production from upstream to downstream operations.